3 Easy Facts About Mhs - Material Handling Supply Inc. Explained

3 Easy Facts About Mhs - Material Handling Supply Inc. Explained

Blog Article

7 Simple Techniques For Mhs - Material Handling Supply Inc.

Table of Contents5 Easy Facts About Mhs - Material Handling Supply Inc. ExplainedThe Best Guide To Mhs - Material Handling Supply Inc.The Main Principles Of Mhs - Material Handling Supply Inc. Unknown Facts About Mhs - Material Handling Supply Inc.Mhs - Material Handling Supply Inc. Fundamentals ExplainedMhs - Material Handling Supply Inc. Fundamentals Explained

This line is called the line of action. Forklift dealer athens, ga. If the base of this line goes outside of the security triangular since a lots is too hefty or too expensive, or because the forklift is not on a degree surface it will tip over. An upright line extending from the center of gravity of the vehicle-load combination must stay inside the security triangular to avoid the forklift from tippingThe various other concept to comprehend is the forklifts facility of gravity. When unloaded, the forklifts center of gravity is right regarding below.

Much heavier lots move the center of mass ahead also further. Raising the tons also shifts the center of mass ahead. In order to avoid the lift from tipping, the combined center of gravity of the tons and the lift have to stay inside the security triangle (at ground level) at all times.

Some Of Mhs - Material Handling Supply Inc.

If you have a balanced tons, the load is unlikely to influence the side-to-side center of mass. https://www.intensedebate.com/profiles/tannergraves30677. If you drive on a sloped surface area, your center of gravity can pass exterior of the stability triangular and the lift can tip. Every forklift has a recognition plate that notes crucial details concerning the vehicle

To make sure that the center of gravity of your forklift stays inside the security triangular, do not attempt to raise anything heavier than the identification plate enables. No issue just how active you are, you have to evaluate your forklift prior to using it. If you do locate something that can influence the safety of the automobile you have to report it right away.

Remember, the driver is liable for the risk-free operation of the forklift. If the forklift is used around the clock, evaluate it either before each shift or after each change.

The Facts About Mhs - Material Handling Supply Inc. Revealed

It is finished in 2 components: the walk-around assessment, and, the seated examination. It's a good idea to have a checklist to make sure you do not miss any actions.

If the forklift is an exterior forklift with pneumatic tires, check the air pressure and look for excessive wear on the tires. A tire with reduced air stress can create the lift to tip when a lots is elevated.

Getting The Mhs - Material Handling Supply Inc. To Work

Check the engine for any kind of indications of wear, loosened connections, or leaks. Look for cracks or deformities in the forks, backrest, pole, and overhead guard. Check the recognition plate to make sure it is intact and understandable.

Begin the engine. Always start the engine while seated in the driver's positionnever while standing together with the forklift. Inspect all evaluates and warning lights, and the battery or fuel level. Obtain aware of the controls. Raise and lower the forks, and turn the mast. Make sure that every little thing functions efficiently and is clearly labeled.

Mhs - Material Handling Supply Inc. - An Overview

Inspect the brakes by depressing the brake pedal. Inspect the steering. Move the forklift ahead a few feet.

Leakages can suggest a hydraulic problem, and fluids left on the floor are a sliding danger. Likewise check this site out seek triggers or flames appearing of the exhaust system. Listen for any unusual sounds. If you find anything incorrect with the forklift during the walk-around or seated assessment, do not run it till it has actually been fixed.

Getting The Mhs - Material Handling Supply Inc. To Work

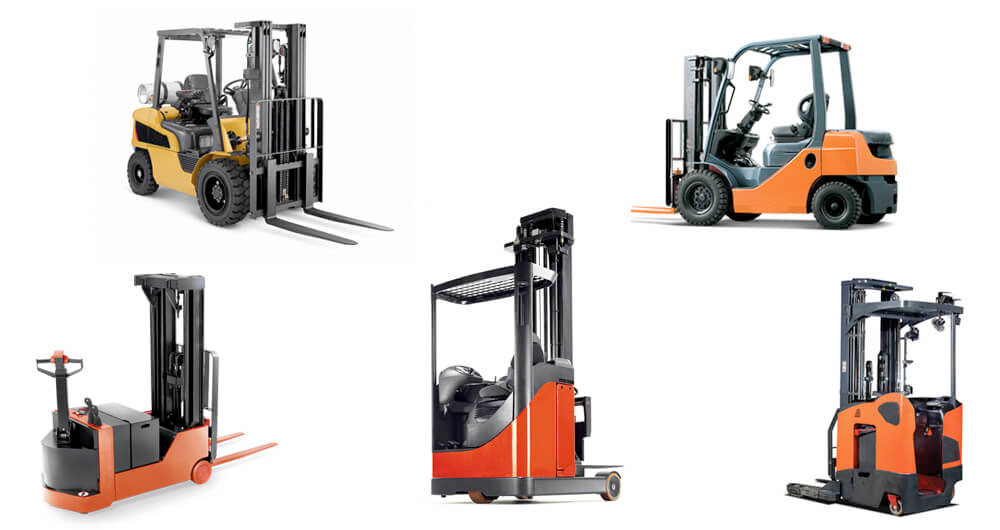

Forklifts have several relocating components and items that enable the forklift to run properly. Understanding the terminology of the components and makeup of a forklift is essential for effective communication with others while on duty - https://www.mixcloud.com/mhsinc30677/. Below are some of the essential attributes and components that make up the anatomy of a forklift vehicle

For most forklifts, the mast is developed toward the front of a forklift and directly in the forklift driver's field of vision. Forklift masts include numerous areas that boost or reduced the forklift carriage together with the forks. These consist of:: Two pole phases: Three mast stages: Four pole areas When choosing a forklift, it is necessary to acquaint on your own with the various functions and terms of a forklift pole: the mast's lift height, the free lift elevation and the prolonged height and the lowered elevation.

Report this page